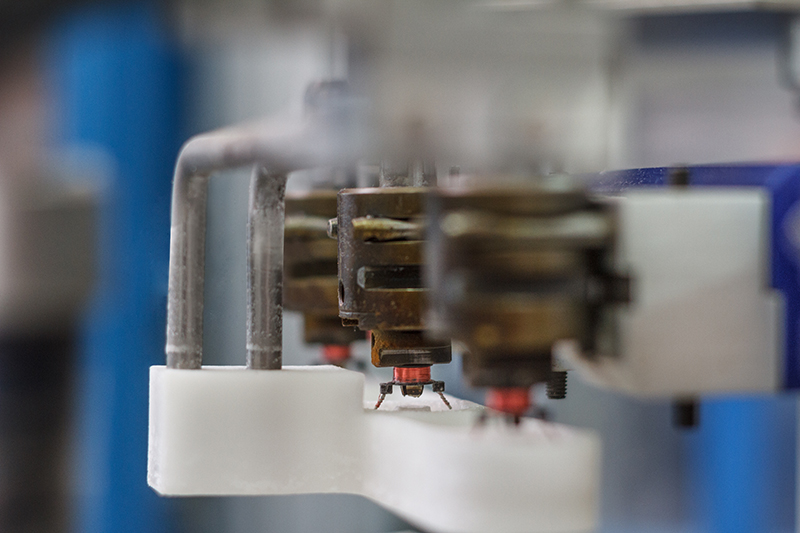

Soldering, thermocompression and resistance welding.

We use different welding technologies, depending on technical requirements for the coil finish.

This part of the manufacturing process is critical for the correct finish in the products. That is why Bobinados Osés is on hand to offer help and advice on reliable welding processes, always guaranteeing these finishes and the proper operation of our coils.

Soldering

Soldering is the basis of all electronic applications, as it allows connections between conductors and between the different components. Soldering is very important in our micro coils.

Thermocompression

Thermocompression welding or bonding is used to make joints using the “indirect heat” principle. The copper wire is joined in two parts by simultaneously applying pressure and heat, with the conductive material itself providing a solid joint.

Resistance

The joint provided by resistance or thermoelectric welding is safe and reliable, brings cost and time savings, and is an ecological, clean process. This process is used in power feedthrough joints in some of our coils.