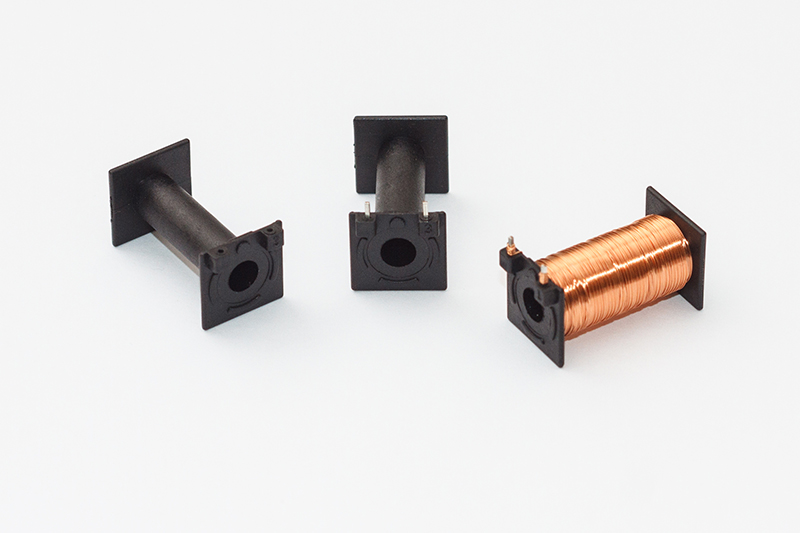

Riveting process

We take on this process with a range of riveting machines.

The final part of the coil manufacturing process is riveting the metal parts for each product, always with a view to offering greater added value.

Pneumatic knee press

This generates a high working force with very precise adjustment and low power consumption. These presses are designed for tasks where high force with short stroke lengths are required for special operations such as marking, riveting, etc. The process has limit switches to ensure a complete stroke, preventing any defective components and helping to guarantee quality assurance.

Manual knee press

Processes are generally automated in order to reduce costs for high production rates, but this type of manual press allows us to do so with smaller production levels.

Rack and percussion press

Designed for applications where a constant force is critical. This press has a quality assurance system to control the process and monitor the force and displacement results.

Radial riveting machine

This radial riveting machine is designed to achieve high-quality joints, efficiently solving any assembly requirement, from deforming small rivets through to obtaining large heads with a range of geometries. The riveting process is supervised using standardised controls made up of basic equipment where the different parameters to be controlled are adjusted and visualised.